Recoil spring extra power improves overall function and feeding which is a common issue in the universal models.

M1 garand op rod spring length.

Regular springs have the coils too close may lock up preventing the bolt to pick up the next round.

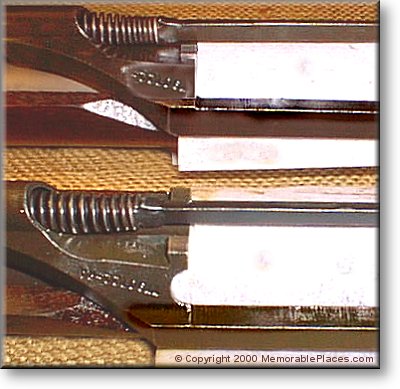

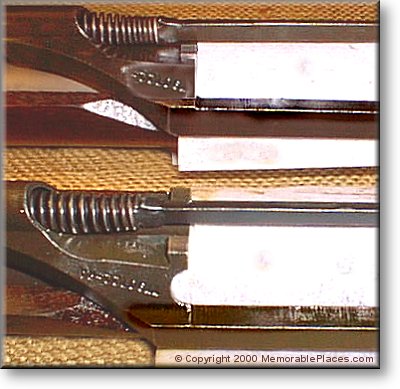

Note the odd bend in the t26 short op rod and the major difference in length of the follower arm spring guide.

Also you can use the same follower rod instead of buying one for 59 95.

The comparable figure for the t44 m14 with gas cut off and expansion system was 05.

2 recoil springs are required per gun.

When an operating rod spring is compressed with a 16lb weight the spring must compress to a length of between 11 75 and 12 75.

Tanker top fitted with smith enterprises muzzle brake.

The op rod spring connects to the follower rod and slides inside the op rod tube.

This spring provides the force required to properly cycle the rifle.

Op rods are made with two bends in the tube they are not made straight so if your tube has a bend it should.

You should use the 1 3 4 front handguard.

The garand guy com has them.

A 5lb weight compresses our spring to 17 1.

Operating rod descriptions and pictures will be of actual rods available except where noted.

And you re good to go.

Tom had this to say about his new garand.

M1 garand operating rods springs and follower rods.

All usgi and gauged to insure serviceability.

Superior over the standard carbon wire springs made during the war years.

11 the operating rod spring is probably the single most critical component to the proper cycling of your m1 garand.

If your gun has a single recoil spring see us m1 carbine.

M1 rifle operating rod springs we went back to the original springfield armory drawings to duplicate the original spring with one exception.

Tom emailed me photos of his new t26 style m1.

Our m1 garand operating rod spring has the following parameters.

Note barrel length and the upper handguard difference.

Our new springs are manufactured from the highest quality 17 7 stainless steel wire available in the industry.